Needless to say it’s hard to predict what the mobility industry will look like in 2030. However, there is no doubt that a number of evolutions and trends will challenge the status quo. This conclusion inspired us to peruse a number of recent studies and consult with a broad range of experts from the energy industry, the automotive industry, the lease sector, the academic world and the logistics industry to get their take on the next 10 years.

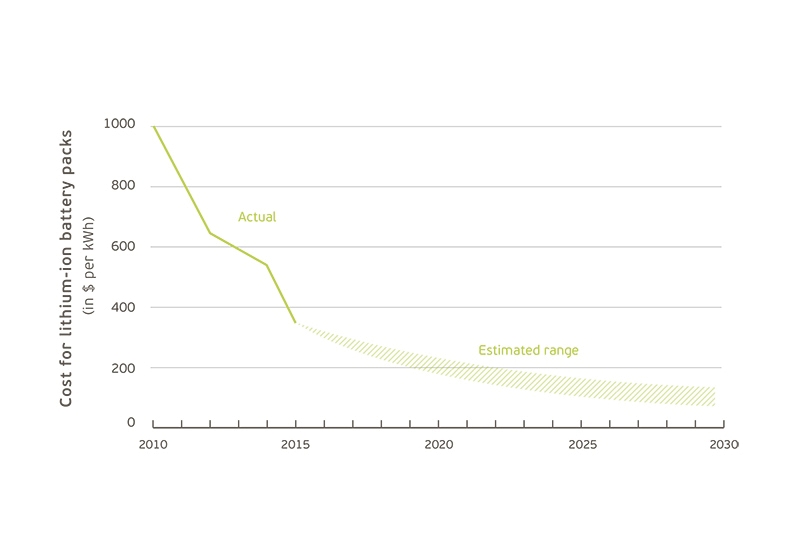

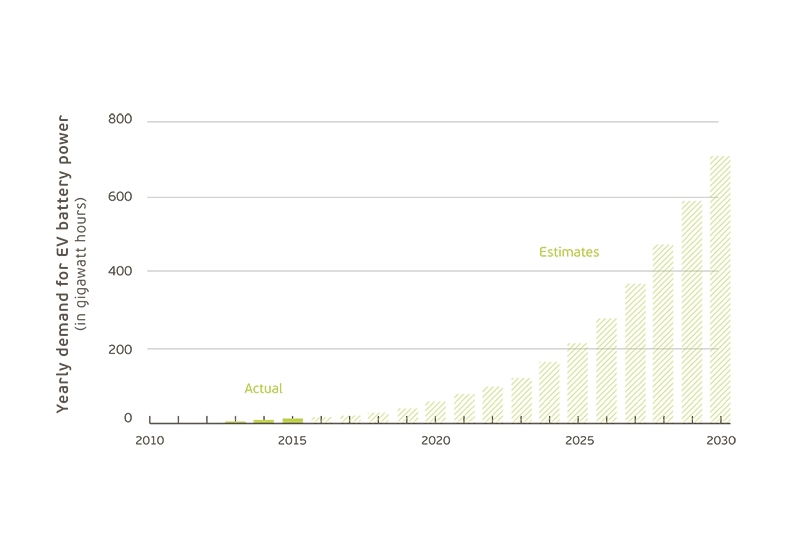

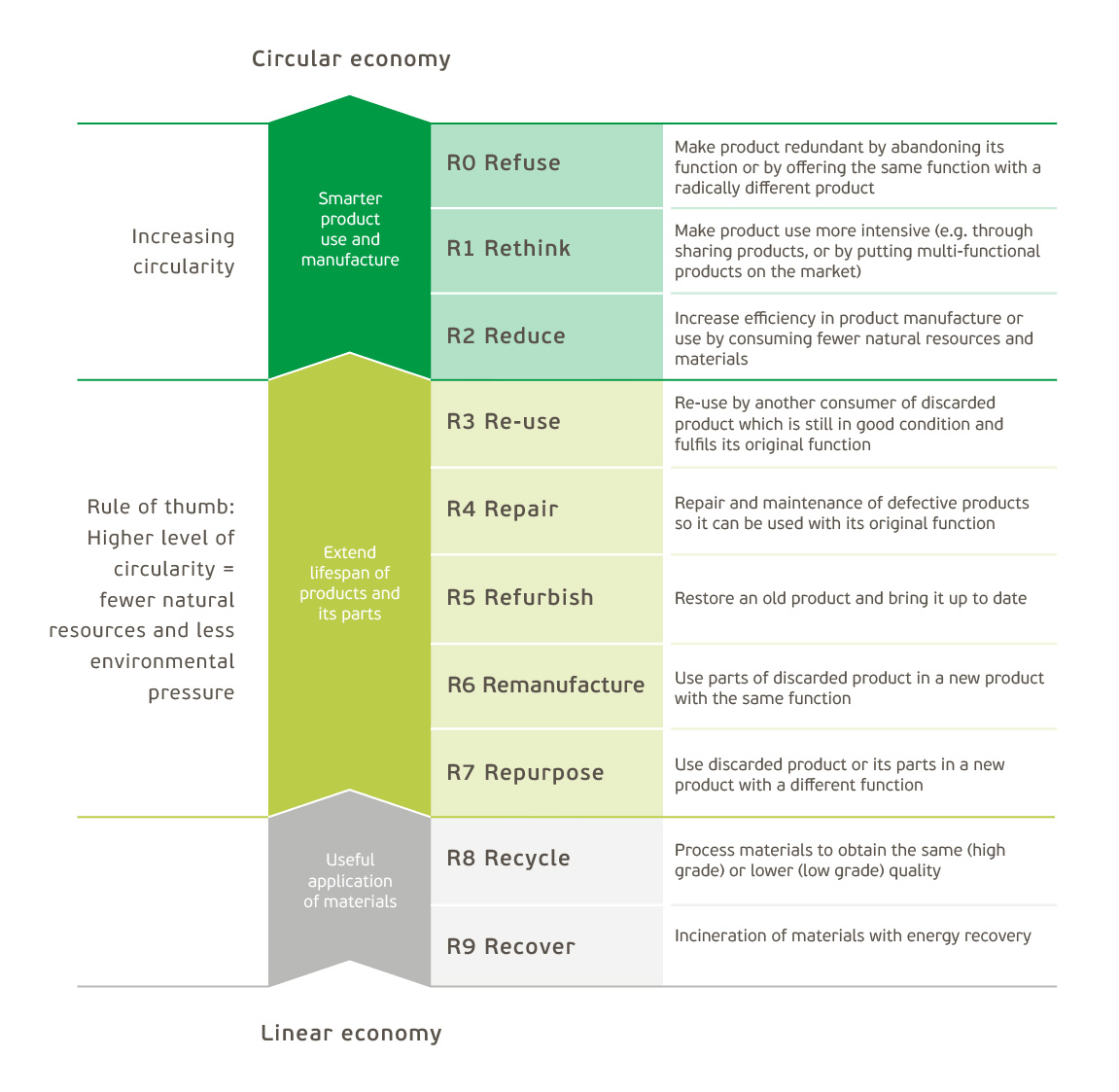

One thing is for certain: all these new and predominantly electric forms of mobility will generate an exponential growth of the number of batteries. Not only do these batteries have to be manufactured, they must also receive suitable aftercare after their first life.

- You can read all about this subject in our e-book ‘E-Mobility Report’.

- Our first e-book ‘E-mobility: What We Can Learn from Norway’ took a closer look at what the best pupils in the electromobility class were doing.

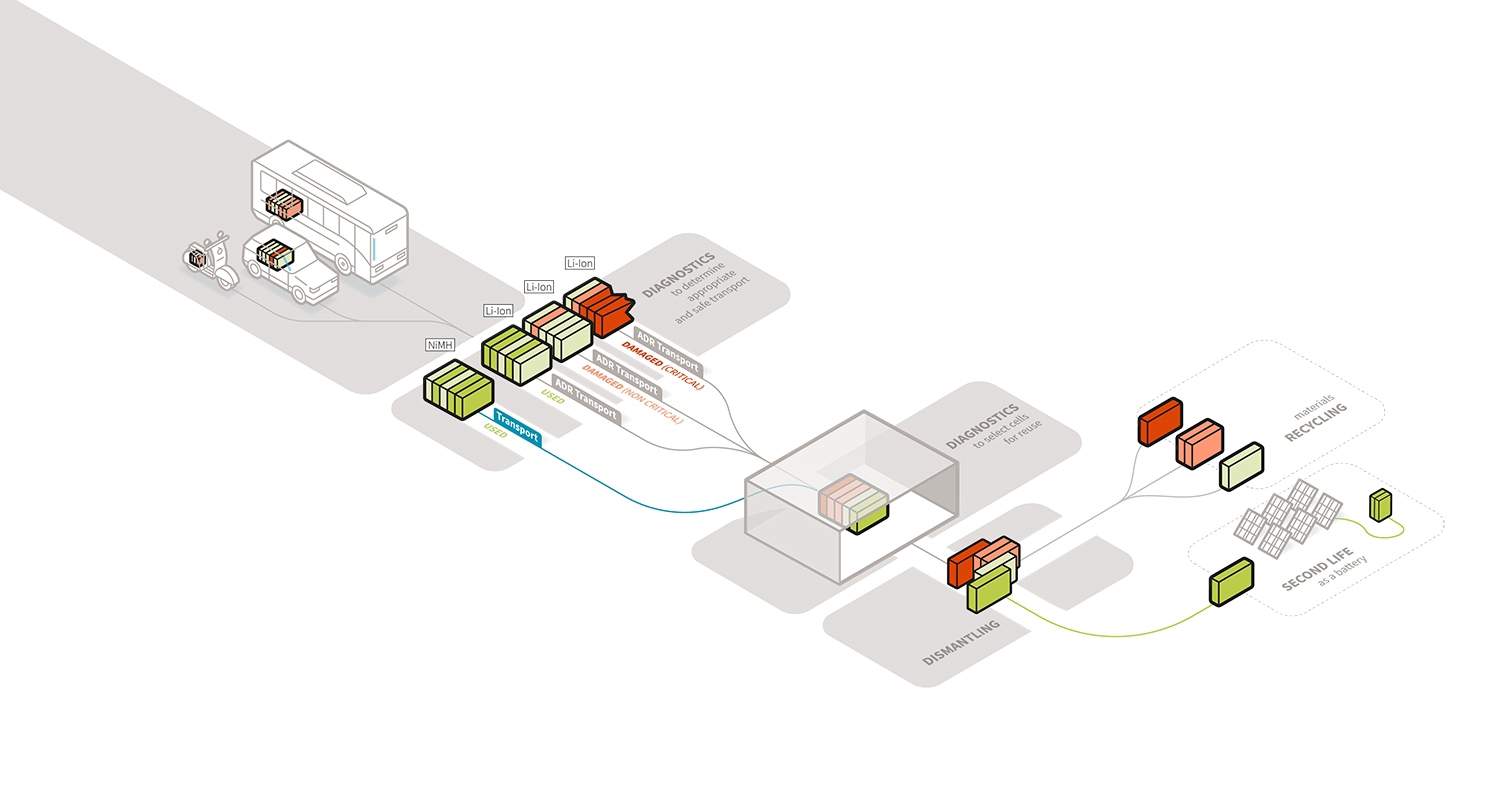

Bebat is the governing body for discarded batteries. Based on its mission and vision and in tandem with sorting centre Sortbat, Bebat has been an indispensable link in the economic value chain of batteries for more than a decade. In the past 6 years Bebat has collected, carefully transported, safely stored and - if the customer so wishes - examined and dismantled well over 10,000 EV batteries.

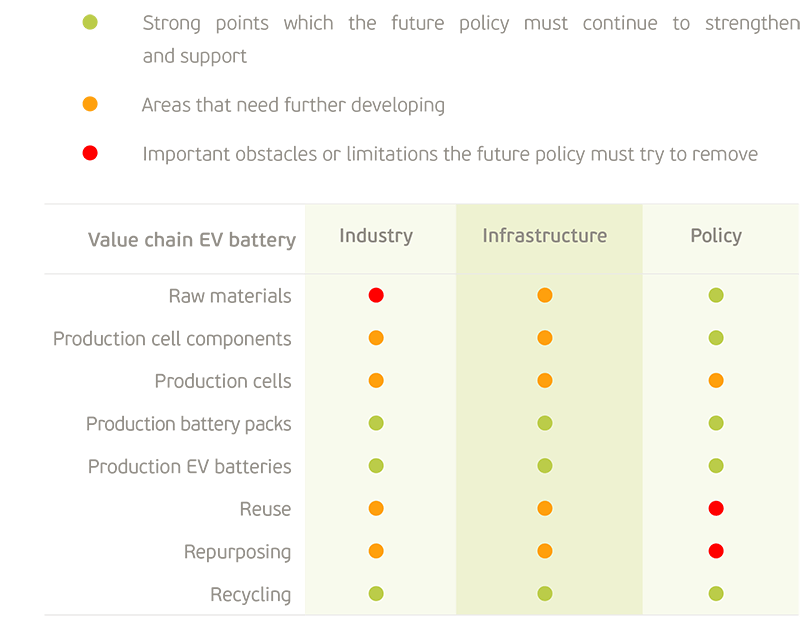

With this third e-book we aim to keep a finger on the pulse and make the necessary preparations to offer Bebat members the most suitable service possible. In other words, the mobility of the future holds major challenges for Bebat as well. As with other battery types, we want to collect these large EV batteries in growing numbers, upgrade the recycling process and reuse the valuable components safely in new applications. We can’t wait to get started.

Bebat, single point of contact for all battery types, wishes you lots of reading fun!